There are different processes of Trichlorosilane available, the mainstream technologies are Silicon Hydrogen Chlorination Process and Silicon Tetrachloride Hydrogenation Process. Silicon Tetrachloride Hydrogenation need to be operate under high temperature and pressure, which lead to high energy consumption, serious corrosion of equipment and large capital investment. This process are mainly used in the downstream of Polysilicon enterprises for recover that Silicon Tetrachloride as a by-product in their existing plant.

SYNOPSIS CHEMITECH built Trichlorosilane plants based on Silicon Hydrogen Chlorination process with its mature technology and good suitability for industrialization, our unique technology has been widely used by most of the Trichlorsilane plants.

BACKGROUND

With the rapid development of the world economic, especially in the sector of fine chemicals, organic silicon industry, electronic products, optical fiber communication and other industries, it provides a huge market space and opportunity for the production of Trichlorosilane and the development of its downstream products.

Trichlorosilane is one of the basic raw materials for the production of Polysilicon and It’s also as an important intermediate materials for the production of Silane coupling agents and other organic silicon products.

Polysilicon material is an electronic material that is purified by some of Physicochemical reactions with Trichlorosilane as raw material to reach a certain purity and is an extremely important intermediate product in the silicon industry chain. It is the main raw material for manufacturing silicon polishing sheets, solar cells and high purity silicon products, and the most basic raw material for IT industry and green energy industry.

Energy is an important foundation for economic and social development. Ever since the industrial revolution, the world’s energy consumption has increased dramatically, with rapid consumption of fossil energy resources such as coal, oil and natural gas, and the ecological environment has been deteriorating, especially greenhouse gas emissions leading to global climate change had caused the serious threats to human activities on the sustainable development. The limited nature resources, development and utilization had brought environmental problems by restriction of the sustainable development in term of economy and society. From the perspective of all countries in the world, conventional energy is very limited, and the one-time energy reserves for each country are not the way to solve the problems.

With the depletion of fossil energy in the world, humans have to look for renewable energy. The abundant solar radiation energy is an important source of energy, is an inexhaustible, non-polluting, cheap, freely use the energy. Solar energy can generate up to 800,000 kilowatts of energy per second to the ground, if we are able to convert 0.1% of the solar energy from earth surface into electricity at the conversion rate of 5%, the annual power generation can reach 5.6 x 1012 kilowatt hours, equivalent to 40 times the current energy consumption in the world. Polysilicon is the basic material of crystalline silicon solar cells, it consume about 8-10 tons of polysilicon for each production of 1MW solar cells. For this reason, The industrialization of polysilicon is the industrial basis for the development of clean, environmental protection and sustainable utilization of solar energy.

As a raw material for the production of polysilicon, trichlorosilane will have a broad market prospect and its construction is also the basis for the development of IT industry and green energy industry. In addition, as the market demand of silane coupling agent keep increasing, so the Trichlorosilane as a raw material will definitely have a wide market. Nowadays, when companies investing in new projects, they will always pursue at the goals of building construction projects with low investment, high output, low consumption, less the emission, good product quality, broad market, long industrial chain and sustainable development of circular economy, resource-saving, environment-friendly and safe production.

SYNOPSIS CHEMITECH has noted the importance of the development of trichlorosilicon production, its advantage is that trichlorosilicon will consume a large amount of chlorine gas, which provides a good production guarantee for the realization of Cl2 /Caustic balance in Chlor-alkali plants. And it bring green and clean energy to us.

APPLICATION

Trichlorosilicon is the main raw material for the production of polysilicon and the basic raw material for the production of organosilane coupling agent. In recent years, with an average annual growth rate of 20% in the organosilicon industry in many countries, the demand for silicon trichloride is increasing rapidly. At the same time, polysilicon production in many countries is still under development stage, the market needs for polysilicon can only depend on import, this making a gap between supply and demand. It is expected that in the next 5-20 years, the production of polysilicon in various countries will have a rapid development, which will drive the rapid growth of the demand in silicon trichloride market. Thus, the production of trichlorosilicon is a project with high value and promising development.

(1) Trichlorosilicon as a silane coupling agent

Silicone products are a new type of chemical materials with excellent performance and unique characteristics, which are used in various fields of national defense, national economic and even people’s daily life. They have developed into a new industrial system that is technology-intensive, capital-intensive, with high added value and occupying a certain position in the national economy, and have enabled the related industries to obtain huge economic benefits. Silicone products are roughly divided into four major products, such as silicone oil, silicone rubber, silicone resin and silane coupling agent.

Coupling agent is a kind of improved additives that can combine two different properties of substances through chemical or physical reaction, which is widely used in composite materials. Coupling agent of pro-inorganic groups and filler surface binding, pro-organic groups and polymer resin entanglement or reaction, using its unique molecular bridge properties to make the surface properties of inorganic filler and polymer materials compatible, thereby greatly improving the physical properties of composite materials, civil properties, thermal properties, optical properties, etc.. Several types of coupling agents commonly used in production are according to their central atoms, mainly divided into silanes, titanates, aluminates, etc.

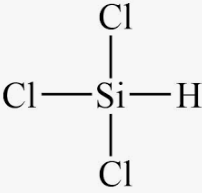

Silane coupling agent is obtained by the addition of trichlorosilane and unsaturated olefins with reactive groups catalyzed by platinum chloride, and then by alcoholysis.

Due to the molecular structure of the reactive groups in silane coupling agent, there is more reaction points on the filler surface, and the molecular organic hydrophobic group contains fewer carbon atoms, short carbon chain. So, as the base resin of the filling plastic in thermoplastics, the use of silane coupling agent brings adverse effects in the processing of the filling system flow performance, plus the price of silane coupling agent is high, therefore, the dosage of silane coupling agent in the thermoplastic is always low. The main application of silane coupling agent is actually epoxy resin or unsaturated polyester resin and other thermosetting plastics. Such coupling agents are mainly used as surface treatment agents for glass fibers, which can improve the mechanical properties, electrical properties and anti-aging properties of FRP.

After decades of development, the use of silane coupling agent has expanded from the traditional glass fiber surface treatment agent to inorganic fillers, sealants, resin concrete, cross-linked polyethylene, resin encapsulation and other materials surface treatment agent.

A. For surface treatment of glass fibers

Silane coupling agent can improve the binding properties of fibers and resins, improve the strength of glass fiber reinforced composites, water resistance, weather resistance and other properties. The use of silane coupling agent in glass fiber accounts for about 50% of the total consumption, which the most common varieties are vinyl silane, amino silane, methacryloyloxy silane, etc.

B. For inorganic filler surface treatment

Silane coupling agent in the coupling of inorganic fillers and resins can be pre-surface treatment of the filler, also can be added directly to the resin to improve the filler in the resin dispersion must and adhesion, improve the process performance and filler plastic (including rubber) mechanical, electrical and weather resistance and other properties.

C. Tackifier for sealants, adhesives and coatings

Silane coupling agent can improve their adhesive strength, water resistance, weather resistance and other properties. Also, it solve the problem of binding in certain materials.

C1 : In structural adhesives metal and non-metal binding, if you use a silane based tackifier, it can be condensed with the metal oxide or with another silanol, so that the silicon atoms are in tight contact with the surface of the glued material. For example, adding silane as a tackifier in nitrile phenolic structural adhesive can significantly improve the binding strength.

C2 : Silane has been commonly used as a treatment agent to glue glass fibers. It can react chemically with the interface, thus improving the binding strength. For example, the peel strength of a neoprene joint is 1.07kg/cm2 if silane is not used as a treatment agent, and 8.7 kg/cm2 if amino silane is used as a treatment agent.

C3 : In order to glue rubber with other materials, silane tackifier has the special function. It significantly improves the binding strength of various rubbers to other materials. For example, if glass is glue to polyurethane rubber, the peel strength of the adhesive is 0.224kg/cm2 without silane as a treatment agent, and 7.26kg/cm2 with silane.

C4 : The binding problems that cannot be solved by general adhesive can sometimes be solved by silane coupling agent. Such as aluminum and polyethylene, silicone rubber and metal, silicone rubber and organic glass, according to the theory of chemical binding, choose the corresponding silane coupling agent, get a satisfactory solution. For example, with vinyl tri-tert-butyl peroxide silane (Y-4310) can make polyethylene and aluminum foil binding; with butadienyl triethoxy silane can make silicone rubber and metal tear strength of 21.6 ~ 22.4kg/cm2.

Other applications of silane coupling agents include: attaching curing enzymes to FRP substrate surfaces, anti-sand in oil well drilling, making masonry surfaces hydrophobic, etc. ….

(2) Trichlorosilane for the manufacture of polysilicon

Trichlorosilicon is not only an important raw material for the manufacture of silane coupling agents, but also for the manufacture of semiconductor and solar cell grade polysilicon.

Polysilicon materials are electronic materials that are purified from trichlorosilicon through a series of physicochemical reactions to achieve a certain purity, which is an extremely important intermediate product in the silicon product industry chain, and is the main and most basic functional material for the semiconductor industry, electronic information industry, and solar photovoltaic cell industry. It is mainly used as a raw material for semiconductors, and is the main raw material for making monocrystalline silicon, which can be used for various transistors, rectifier diodes, silicon controllers, solar cells, integrated circuits, electronic computer chips and infrared detectors, etc.

Trichlorosilicon plays an important role in solar cells, glass fibers, reinforcing resins, precision ceramic fibers and optical fiber protective films, and plays an indispensable and important role in these industries.

(3) Other roles of silicon trichloride

In recent years, silicon trichloride has been used in the pharmaceutical industry. Silicon tetrachloride, the main by-product in silicon trichloride plant is also the main raw material for the manufacture of silicones, and its finished products include silicate esters, silicone oils, high-temperature insulating paints, silicone resins, silicone rubber and heat-resistant gasket materials. High-purity silicon tetrachloride is also an important raw material for the manufacture of high-purity silicon dioxide, inorganic silicon compounds, quartz fibers and optical fibers.

OUR ADVANTAGE

We built high quality Trichlorosilane plants for our clients with a main content of Trichlorosilane at >99.5:

-

New technology provide by Synopsis Chemitech with more than 9 main sub-processes for the production of Trichlorosilane. It will save 90% of the hydrogen consumption.

-

We use a dry tail gas recovery process to recycle the production by-products and save up to 60% of the consumption of silicon trichloride.

-

We recycle waste heat from the trichlorosilane synthesis furnace to save steam consumption for distillation heating.

-

We replace “atmospheric distillation” with “micro-pressure distillation” in each distillation column of our trichlorosilane distillation unit, appropriately increase the operating temperature of each distillation column, and use circulating cooling water instead of low-temperature freezing medium to save energy.

-

The modern facilities of the plant are controlled by DCS system, and the process can be 100% computer-controlled to save energy.

-

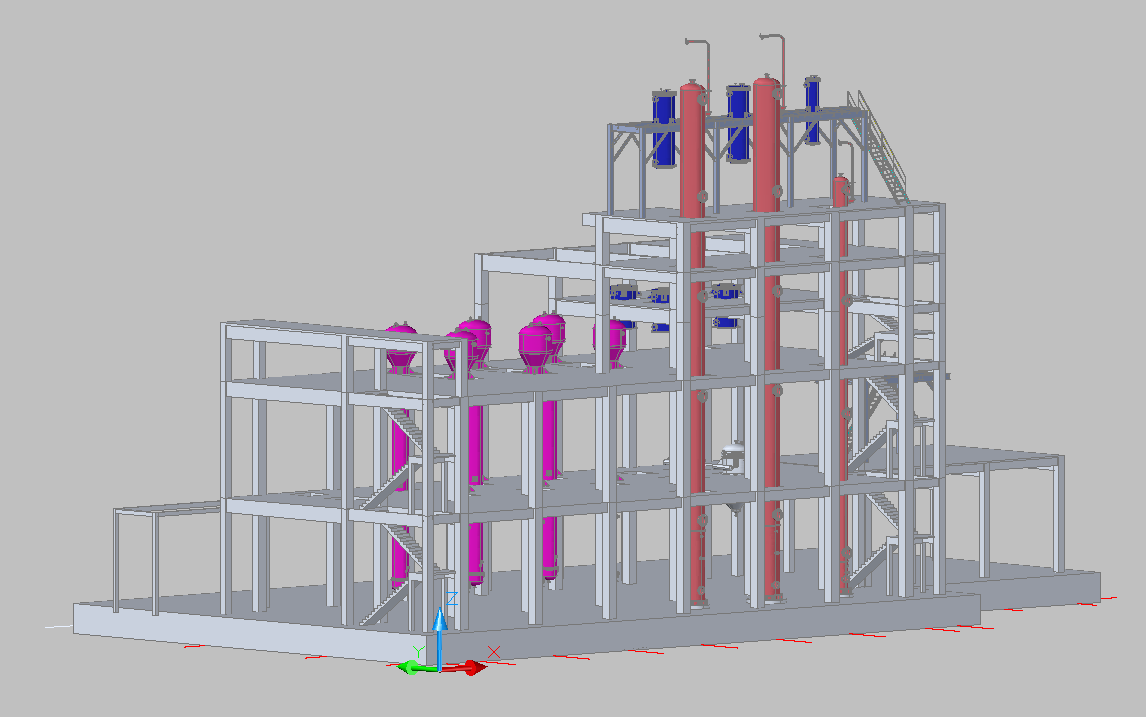

We use 3D design to ensure a rational plant layout and smooth process flow to ensure a high capacity with the most economical clean room area.

For more information please contact info@synopsischemitech.com;