MEMBRANE ELECTRODE (CHLORINE ELECTRODE)

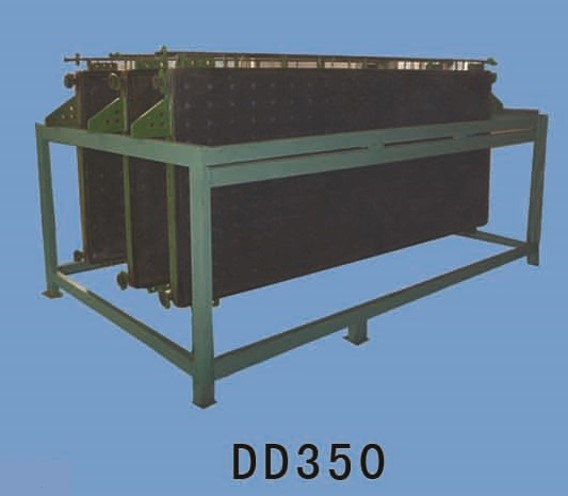

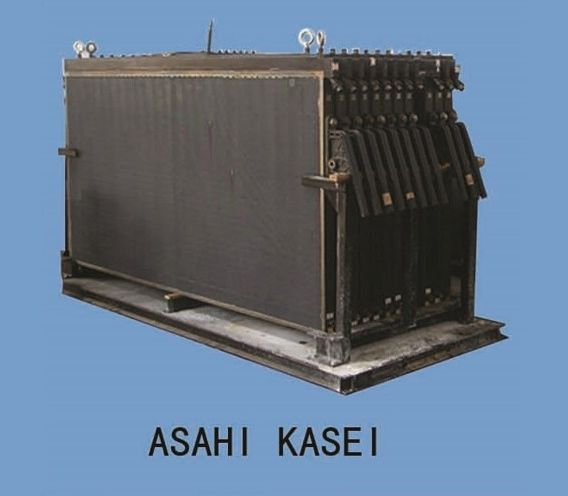

Synopsis Chemitech provides Electrolyser Refurbishment services for the membrane electrolyzer. Our electrolyser refurbishment is more for production of chlorine (Cl2); caustic soda (NaOH); potassium hydroxide (KOH) & hydrogen (H) etc. Our advanced coating technology with process technical suits all kinds of Membrane electolyzers (Both anodes and cathodes). Examples include Asan Kaser 2.7m²; Asahi Glass (F1, F2, B1, M3); Bluestar (BCMW) 2.7m; DE NORA (DD350 & DN350); Chlorine Engineering (BiTAC); MGC & ExL; LURGl, ICI (FM21sp) and the INEOS (BiChlor) etc.

Our company adopted internationally advanced coating technology and process technical for the electrolyser refurbishment. We can refurbish any kind of old electrolyser and the performance close to the new one. The Coating products made by precious metal have the specialties with lower potential, higher current efficiency with long life cycle. We are able to customized the electrolyser according to client’s requirement with best quality. Our electrolyser refurbishment technology and service will make great economic benefits to customers.

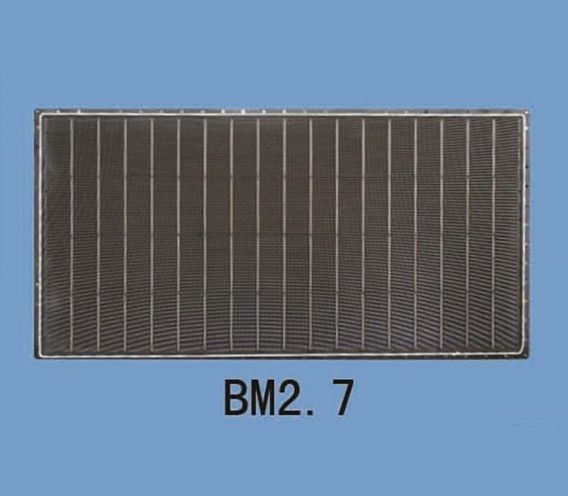

Modification of Cathode By Zero Gap Technology

The cathode of zero gap electrolyzes are mainly composed of collector plate, elastomer and cathode mesh. Current distributor made by nickel mesh which is same as the cathode mesh of the traditional electrolyzer with natural circulation and its without active coating. Cathode mesh is made of nickel wire which is bended by mechanical embossing, so that it has a nature of springiness. Cathode mesh is made of nickel wire with coating and specially processing smooth surface. Cathode mesh fixed on the frame of electolyzer by Ni strip. After membrane is installed, cathode & anode will stay closely and the actual polar distance is the same as the thickness of membrane so that the gap between electrodes are minimized and that is zero gap electrolyser.

Zero gap electrolzer is easy to handle with smooth operation. Compared with the traditional electrolyzer under same current density, the voltage of Zero gap electrolyzer can be reduced by more than 150MV, power consumption reduced by 100-150KWH per ton of Caustic soda (as 100% NaOH). Our advanced Zero gap electrolyzer will help you to reduces the cost significantly.

Feature:

1. Suitable for Refurbishment of electrolyzer or upgrade to next Generation.

2. Mechanical injuries to Membrane will be protected by elastic mesh and improve the distribution of DC current.

3. Nickel materials to be used for Refurbishment works increases the life of electrodes significantly.

4. Advanced coating technology improves the cathode coating performance.

OXYGEN ELECTRODE

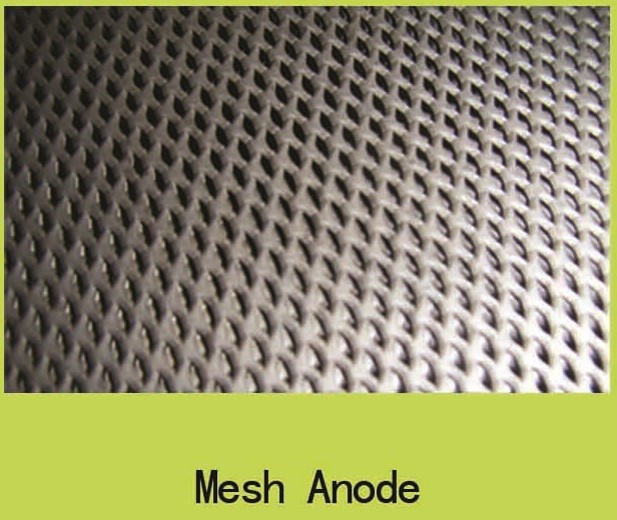

The oxygen electrodes made by our company are widely used in electrolytic metallurgy and Electroplating industry. This new dimension stable electrode is able to reduce the operating costs with improvement in equipment performance and increases the capacity of production. The advantages are as follows:

• In Good Stability of Dimension.

• The diversity of geometric shapes.

• Good stability for both electrochemical & chemical properties in the operation.

• Good electric catalytic activity.

• The potential of anode is low and not sensitive for the change of current density.

• Save power consumption.

• No need for regular maintenance.

• No pollution with long life.

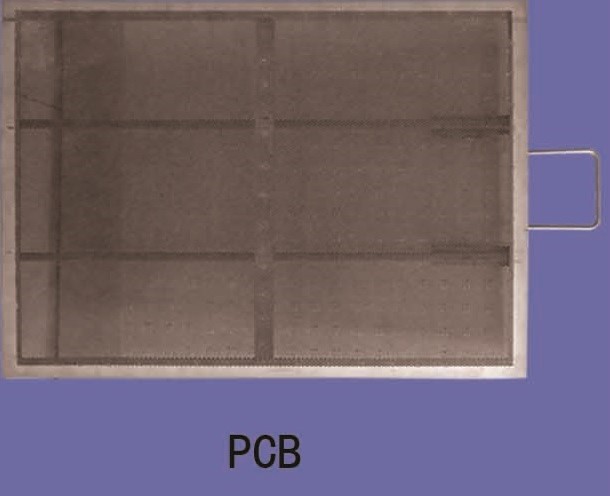

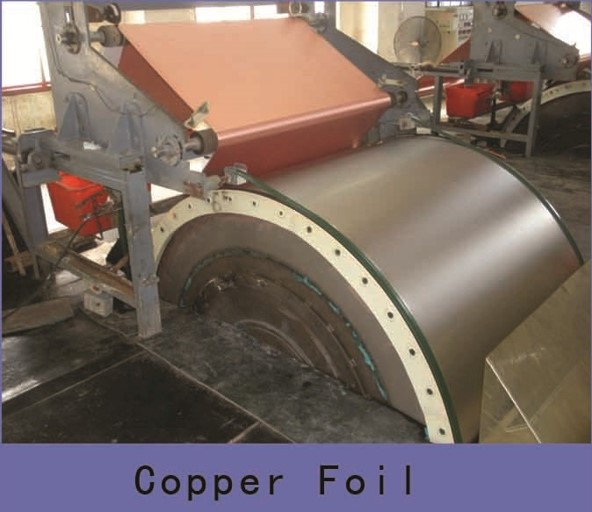

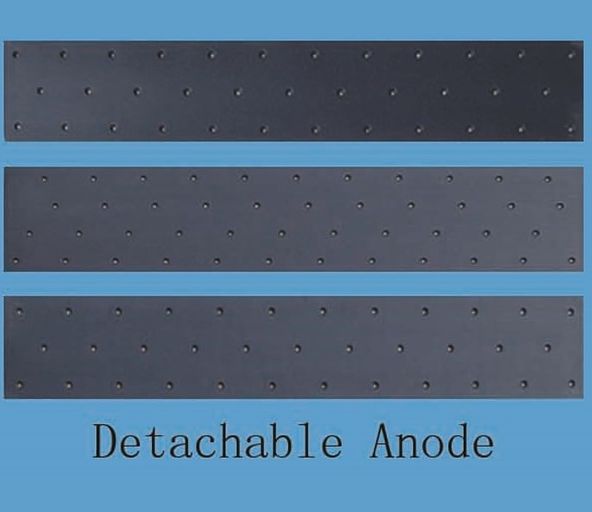

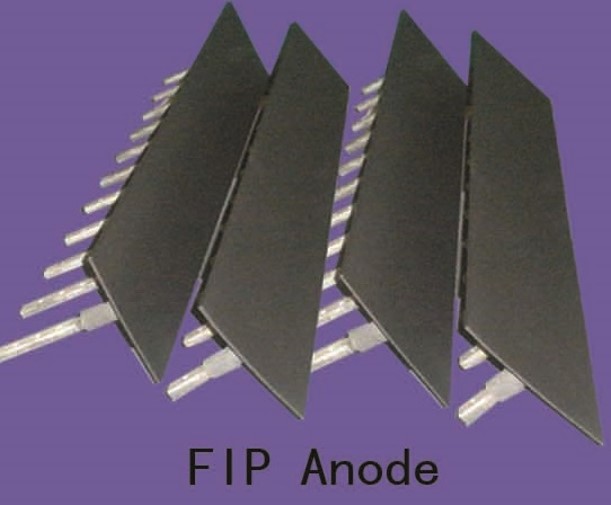

Copper Foil Anode

Copper Foil Anodes are applicable for the production of electrolytic copper foil and copper Clad Laminate. Copper Foil is the main raw materials for the printed circuit board. In the copper foil production process, the radial anodes is used. FIP bar anodes, Detachable anodes and post-processing plate anodes. Working conditions are as follows:

• Current density: ≤8KA/m²

• Medium (Cu): 70-80 g/L

• H2SO4: 100-1408/L

• Temperature: ≤60°C

Used for Printed circuit board (PCB/PWB) and Plating

When processing the acidic copper plating for the circuit board, adding some organic additives are necessary so that the electric plating surface can be smoother. These organic additives must be under optimized concentration in order to generate high quality products. For this process, our company developed special coating anodes to reduce the destruction of the organic matter and can be used as substitute of soluble copper anodes in the circuit board industry.

CHLORATE SPECIAL ELECTRODE

We provide the services of Refurbishment for various types of chlorate electrodes (or make new one). We provide the anodic coating for chlorate production based on new process with consistent performance. It can enhance the electrolytic efficiency and reduce the O2 as by-product from the production process, therefore the operation cost of chlorate plant is reduced.

• NOREL META CONTENT: ≥12g/m²

• SEP: V≤1.130 (VS.SCE)

• POLARIZABILITY: ≤40mv

• ACCELERATED LIFE: Min ≥3500

• CELL VOLTAGE: 2.8 – 3.0V

• CURENT DENSITY: 2000 – 3000 (A/m2)

• CURRENT EFFICIENCY: ≥93%

• LIFE: ≥6years

We provide engineering design and manufacture of special electrode based on client requirements.

Cathodic Protection Anode

Cathodic protection is one of the most effective ways which prevents the corrosion of metal electrochemically. It by supply of some cathodic current for protected metal. In order to from the cathode polarization, when the metal potential falls below a specified value, the corrosion of anodic dissolution process will be effectively restrained. The cathodic protection for anode which is produced by Synopsis Chemitech can be used as a Part of cathodic protection system by External electric current system. They are widely used in the steel structure; reinforced concrete; underground piping network; ground storage tank; sluice; dam; water tanks; bridge; wharf and ocean engineering etc. It will increase life of the system significantly.

Anodes for Surface Treatment of Electroplating Industry

We produce the various anode coating which suits the requirements for different electroplating industry including:

1) Anodes for galvanization / tinplating (EGL / ETL)

2) Anodes for Chrome plating & electrophoresis plating

3) Anodes for other plating/surface treatment auxiliary anodes.

Anodes for recycling copper from Etching liquid.

Anodes for Organic electrolysis synthesis.

Anodes for Electrolysis / extract Co, Ni, Cu, Zn etc. Various kinds of non-ferrous metal.