Calcium Hypochlorite Manufacturing Plant

70% Calcium Hypochlorite

Calcium Hypochlorite also known as the high-efficient bleaching powder, it is an efficient bleaching agent containing chlorine. The main component is Calcium Hypochlorite but depending on the production process it also contains Calcium Chloride, Sodium Chloride and Calcium Hydroxide and so on. The concentration of activated chlorine in calcium hypochlorite usually at 70% due to the good stability, convenient to handle / transport / store.

It can be used as an efficient bactericide, disinfectant and oxidant. The product is widely used in the chemical, military, food and health industries. It can also be used for sterilization such as disinfection of the home, catering, drinking water, epidemic / disease disinfection, prevention and bleaching for cotton-ramie textiles, pulp, cotton cloth, silk, fibers and others.

As of today, the products generated from Calcium Hypochlorite plant built by Synopsis Chemitech with related technologies has been sold to North America, South America and Europe. All the products are able to achieve the requirement and fulfill local standards.

Advantages of Synopsis Chemitech’s Technologies

Synopsis Chemitech newly built Calcium Hypochlorite Manufacturing Plant based on “Sodium Process” technology with 70% concentration is one of the most advanced technologies in the world.

In the traditional “calcium process”, the hydrated lime will be made into slurry type, in which the lime reacts directly with chlorine gas, and the reacted products will be separated from the crystallizer, then final product the Calcium Carbonate will be produced after drying.

Compared to our “Sodium Process”, the Calcium chloride in the reactant will not fully converted, so the contents of Calcium chloride in the product will be at higher side, therefore, the effective chlorine will generally be at about 65% only.

Due to the high content of Calcium chloride, the products have strong hygroscopicity and less stability thus it is not suitable for long-term storage and transportation.

To solve the above issues, Synopsis Chemitech developed new technology which uses “NaOH Process” for Calcium Hypochlorite manufacturing plant at 70% concentration and has been recognized by all our clients. Our technology is as below:

CaCl2 is converted from NaOCL to Ca(OCl)2 and NaCl is generated into slurry due to the chemical properties. NaOH is more active than Ca(OH)2, therefore, Cl2 gas will react with NaOH and form NaOCl first, then only the chlorine gas will react with Ca(OH)2 to form Ca(OCl)2 and CaCl2 when all the NaOH have completely reacted, CaCl2 will be converted to Ca(OCl)2 by NaOCl in the slurry and produce the NaCl.

With chlorination going on, the concentration of Ca(OCl)2 will be increasing continuously, and Ca(OCL)2 will react with Ca(OH)2 to form Ca(OCl)2·2Ca(OH)2 precipitation when the concentration of Ca(OCL)2 reached at 4.0% ~ 5.5%,……For more details information please contact info@synopsischemitech.com….

The new Calcium Hypochlorite process as a derivative from Chlor-alkali industry developed by Synopsis Chemitech is based on fine chemical technology. Our process has the following technical advantages & characteristics.

1. Due to the good stability on quality, therefore, there are no restrictions on exports to all countries.

2. Caustic soda, liquid chlorine, chlorine gas produced from the chlor-alkali plant can be used as raw materials to produce the Calcium Hypochlorite plant. Also, chlorine gas can be supplied to our system directly from the existing chlor-alkali plant instead of liquid chlorine for the Calcium Hypochlorite. Therefore, the total operation costs will be reduced significantly.

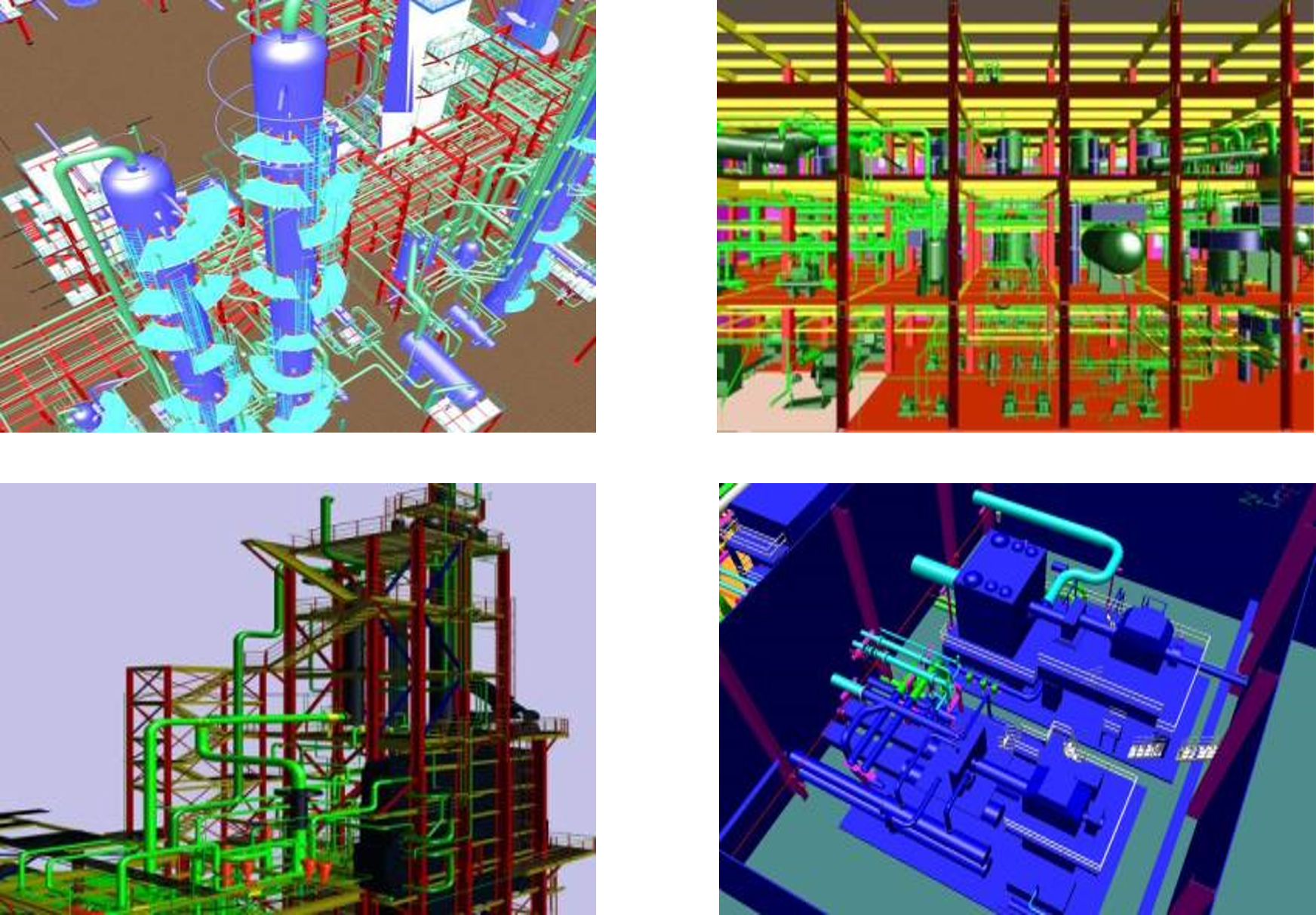

3. The technology of Calcium Hypochlorite plant built by Synopsis Chemitech were based on our own special formulas and controlled by DCS. The production will be fully automated, which can reduce the labor intensity and ensures the products quality.

4. The equipment used for the whole system will fabricated in Singapore, especially these centrifugal type separators for primary & secondary reaction slurries; drying devices and purification process have reached the most advanced level in the world. Synopsis Chemitech has developed our own unique technology with strong competitiveness and the product quality reaches the international standards with lowest consumption.

5. The new methodology of Calcium Hypochlorite provided by Synopsis Chemitech is the latest technology which has been analyzed by HAZOP and applied to various Chemical plants. The performances were recognized by existing owners.

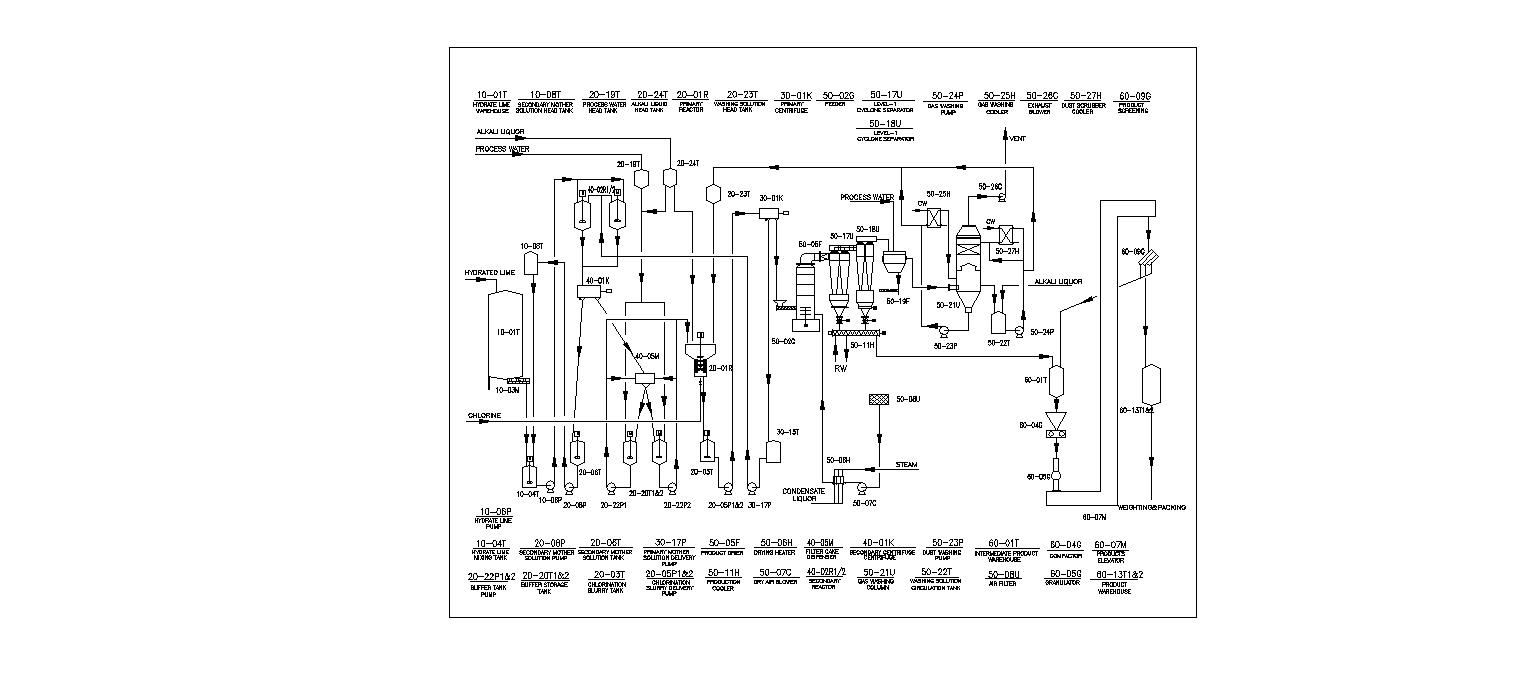

Principle of Synopsis Chemitech’s Technologies

1. Production Principle of Calcium Hypochlorite NaOH, Ca(OH)2 and Cl2 are the major raw chemical materials for calcium hypochlorite production with the concentrate of 70% (active chlorine)

……for more information please contact info@synopsischemitech.com.

2. Chemical Reaction Main Reaction

2NaOH + Cl2 → NaOCl + NaCl + H2O

2Ca(OH)2 + 2Cl2 → Ca(OCl)2 + CaCl2 + 2H2O

CaCl2 + 2NaOCl → Ca(OCl)2 + 2NaCl

Ca(OCl)2 + 2NaOH → 2NaOCl + Ca(OH)2

Total Chemical Reaction

Ca(OH)2 + 2NaOH + 2Cl2 → Ca(OCl)2 + 2NaCl + 2H2O

Side Reaction

Cl2 + H2O → HCl + HOCl

NaOCl + H2O + Cl2 → 2HOCl + NaCl

Ca(OCl)2 + 2H2O +Cl2 → 4HOCl + CaCl2

OCl- + Cl- + H2O → 2OH- + Cl2↑

OCl- + Cl- + CO2 → CO32- + Cl2↑

OCl- + 2H2O → 4OH- + 2Cl2↑ + O2↑

2OCl- → 2Cl- + O2↑

3OCl- → 2Cl- + ClO3-