Engineering Services

Pre-Sales Service

Synopsis Chemitech provides professional and comprehensive chemical plant engineering services guides and directs your investment. Introduce the situation and product categories of our company.

• According to the international / local market demands, guide the users to choose the right product category.

• According to the production demand and the investment scale, guide the users to choose the right Technologies; Process; Equipment.

• Accompany on-the-spot investigation on production, introduce the production processes and explain the difficult problems.

• According to the actual situation, work out a flexible investment solution for you.

• We provide our existing matured Technologies & Process for our clients or Comprehensive technology for taking a process from the research and development scale to the commercial production scale plant, in a logical and systematic manner, while always considering the customer’s needs and requests.

• Our directory listings are organised around the contracts they execute including Feasibility Studies, FEED Contracts, EPC Contracts, EPCm Contracts, EPCI Contracts, Design and Build Contracts, Early Civil Works Contracts.

Feasibility Studies

Synopsis Chemitech will prepare conceptual design which shows outline of new chemical plant projects. Based on the blueprint thereby prepared, we carry out feasibility studies (an investigation of its possibilities as a business, abbreviated Feasibility Studies), which considers the profitability or otherwise of the business from various perspectives. Feasibility studies are usually performed in several stages repeatedly and the precision of studies improve. Then finally, clients can proceed next steps, if it is judged that new projects can yield high profitability.

Based on its abundant record of achievement in plant construction in various fields, Synopsis Chemitech will undertake the initial stage of the feasibility study as its starting point and commencing with a market survey, selects the production process, investigates the optimum configuration for process utility equipment, calculates equipment and operating costs, and produces an optimized highly economical proposal that considers the entire plant life-cycle.

Feasibility studies carried out by Synopsis Chemitech’s possess the following special characteristics:

• We propose a process selection and optimum equipment configuration that meets the needs of the customer.

• We give a highly accurate estimate of construction costs based on data from an extensive record of achievement in construction projects.

• We provide an efficient investigation supported by engineers of long experience and a rich fund of data.

On-Sale Service

Our Meticulous and scientific ongoing engineering service makes your choice more worry-saving and reliable.,/p>

Basic Input Engineering

Basic input engineering is conducted after completion of Conceptual Design or Feasibility Study. Under this stage, before start of EPC (Engineering, Procurement and Construction), various studies take place to figure out technical issues and estimate rough investment cost. this work is normally contracted to EPC contractors, The product of the activity is called “FEED Package” which amounts up to dozens of files and will be the basis of bidding for EPC Contract. It is important to reflect client’s intentions and project specific requirements in to the FEED package without fail, in order to avoid significant change during EPC Phase. The FEED Work takes about 10months in case of large-scale project as it is essential to maintain close communication with client and it is a common practice that client stations at Contractor’s office during the work execution.

Detail Engineering

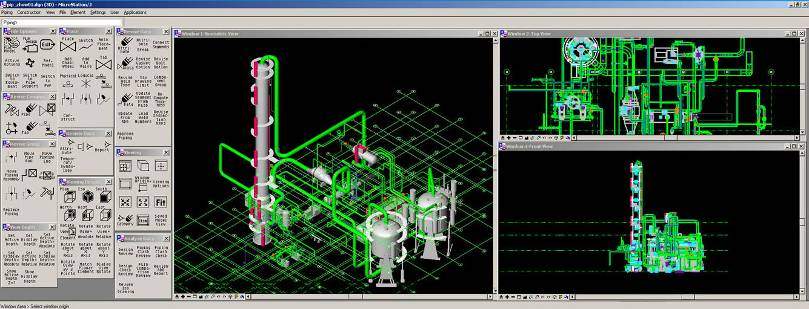

Following FEED is the Detailed Design (Detailed Engineering) phase, which will consist of procurement of materials as well. This phase further elaborates each aspect of the project / product by complete description through solid modeling, drawings (3D Design) as well as specifications. Synopsis Chemitech will prepare and submit few thousand of engineering documents according to package / project’s requirement.

The simulation and design of the complete plant (system) will be provided by Synopsis Chemitech and also the multiple simulation runs which are required to optimize the number of contacting stages for each upstream & downstream. Our advanced process simulation techniques using ASPEN, CHEMPRO, CHEMCAD, BatchReactor, MS Excel, CAD and PDMS 3D model design. PDMS can be used for collision inspection, timely detection, errors correction and avoid that on-site construction problems. PDMS modelling consultation software can be used for realize resource sharing among of different majors which is conducive to reduce the errors of design and ensuring the design quality.

A detailed equipment specification will prepare for each package of system, included all the reactors / separator, cooler, pumps, filters, tanks, vessels, piping, instruments with related associated DCS controls. This specification will submit to client for final approval before place order. In addition, duty specifications were prepared by Synopsis Chemitech for the project should be as a part of manual.

After-Sales Service

Thoughtful and prompt after-sales service provides support and guarantee for your benefits.

-

Provide the engineers for supervision of erection & installation on site and technicians to carry out the installation and debugging of plants / equipment for the international clients.

-

Train the users to command the plant and guide them for safe production.

-

Explain the routine maintenance of system / equipment carefully and remove common faults. Include repairing works.

We are responsible for all the repairs that caused by our quality problems within warranty period. International accessories are generally delivered by sea or alternative by DHL. TNT for urgent issues. The International clients who have any questions on after-sales service can directly send email to our designated mailbox. We will answer your questions within 12 hours and solve various problems for the customers in time. For some countries whose visas are difficult obtain, customers can also send their technicians to our company to receive free guidance and training.

-

Provide team and support clients for chemical plant operation according to the actual situation, the chemical plant operation by synopsis chemitech will be worked with client’s engineers cum training.

-

Synopsis Chemitech is a provider of in-house industrial services of the highest quality for our customers across the globe. These include emergency services to ensure the quickest possible restoration of plant availability, the fabrication of all technological systems and components in our portfolio, as well as the production, repair and replacement of spare parts and components.

Synopsis Chemitech bring the whole project together into one place and using our excellent project management skills, manage all phases of planning and construction across a range of trades:

- Chemical Plant Safety

- Chemical Plant Engineering

- Chemical Plant Controlling

- Procurement for Chemical Plant During Execution Stage

- Expediting Chemical Plant Execution

- Chemical Plant Construction Management

- Chemical Plant Commissioning

- Documentation for Chemical Plant During Execution Stage

- cGMP-compliant DQ, PQ, IQ, OQ for Chemical Plant During Execution Stage

Synopsis Chemitech offers you experienced EPCMV teams led by successful project managers with extensive experience in your industry. at the same time, we not only focus on professional competence – we also place great importance on our employees having a strong emotional quotient (EQ).

Synopsis Chemitech’s comprehensive process methodology can be tailored to meet the specific requirements of your project and to replicate your internal regulations in the best possible way. what’s more, we are in keeping with the times and, accordingly, are able to offer you Engineering 4.0 with our tools. At Synopsis Chemitech, “Engineering 4.0” is not just a buzzword – we are actively involved in efficiently implementing smart software tools to reduce the duration of projects.

We will provide you with a state-of-the-art, future-proof facility. General planning by Synopsis Chemitech combines specialist knowledge and team skills with personal commitment. We believe that our reputation and quality are importance to our customers!

We believe that the client’s benefits and desires are importance to us!