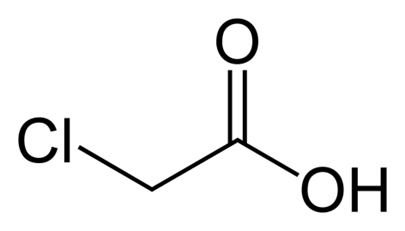

After a long period of research and development and production practice, Synopsis Chemitech has developed Acetic Anhydride Catalyzed acetic acid chlorination method with continuous MCAA production process.

Major Raw Material: Acetic anhydride Acetic Acid; Chlorine gas and others; Cl2 gas and NaOH to be build inhouse by later stage and supply to both MCAA plant.

Mono-Chloroacetic Acid (MCAA) plants build by Synopsis Chemitech based on Non-sulfur technology will have following advantages:

| 1. |

Our technologies covered both Food Pharma Grade & Detergents Grade. |

| 2. |

Non-sulfur technology. |

| 3. |

High products quality (Monochloroacetic acid ≥98-99%). |

| 4. |

Zero waste, 100% recirculation internally. |

| 5. |

Good hydrogenation with Low investment. |

| 6. |

Modern plant. Higher level of automation process to increasing that precision control. Full automatic centrifuge is used for continuous separation of products with stable output. |

| 7. |

Lower that labor intensity to avoid the mistake. |

| 8. |

Wide range of raw materials available in most of counties. |

| 9. |

Lower requirements for production conditions. manufacturers easy to meet the process requirements. |

| 10. |

Standard single set of reactor to procedure high capacity up to 10,000 tons / year. |

| 11. |

Strong adaptability to meets most of production conditions. |

For more information, please send email to info@synopsischemitech.com